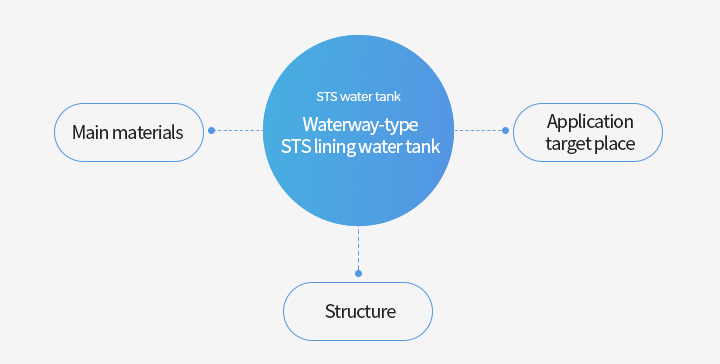

Pullout load comparison test between normal chemical anchor and the anchor construction where patented technology has been applied

Pullout load comparison test between normal chemical anchor and the anchor construction where patented technology has been applied

38.4% improved compared to the conventional anchor construction

38.4% improved compared to the conventional anchor construction

Possible to simplify construction method with strong adhesive power

Possible to simplify construction method with strong adhesive power

Effect of reducing construction costs

Effect of reducing construction costs

Classification |

Unit |

Test result |

Pullout load |

kN |

Normal chemical anchor construction (conventional method) |

Butterfly nut+ chemical anchor construction (our technology) |

13 |

18 |

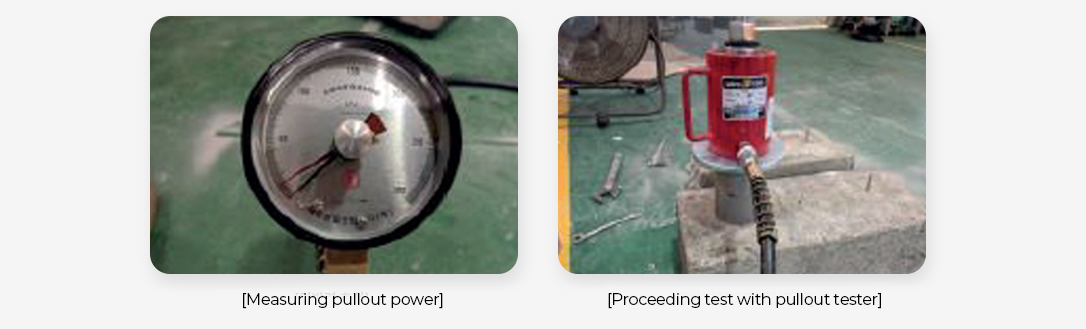

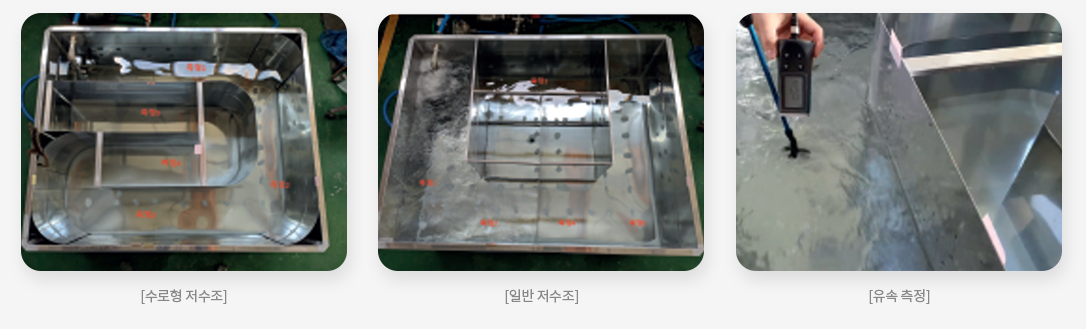

일반 도류벽 저수조와 곡면패널이 적용된 수로형 저수조의 유속 비교 시험

일반 도류벽 저수조와 곡면패널이 적용된 수로형 저수조의 유속 비교 시험

정체된 기존 제품에 비해 수로 형태의 물길로 유속 발생

정체된 기존 제품에 비해 수로 형태의 물길로 유속 발생

강한 부착력으로 시공 공법 간소화 가능

강한 부착력으로 시공 공법 간소화 가능

정체구역 방지 및 잔류염소 접촉시간 증가

정체구역 방지 및 잔류염소 접촉시간 증가

Classification |

Unit |

측정#1 |

측정#2 |

측정#3 |

측정#4 |

측정#5 |

수로형 저수조 |

km/h |

0.8 |

0.2 |

0.1 |

0.1 |

0.1 |

일반 저수조 |

km/h |

0.4 |

0.1 |

0.0 |

0.0 |

0.0 |

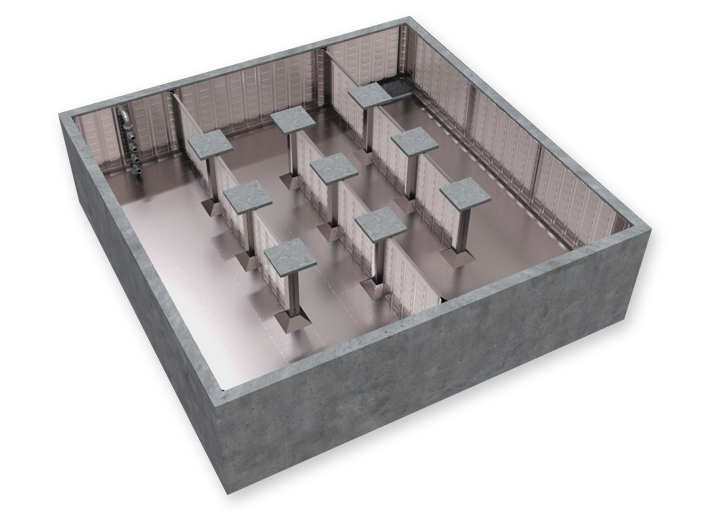

Waterway-type STS lining water tank

Waterway-type STS lining water tank